Get instant access to this case solution for only $19

AIC Netbooks Optimizing Product Assembly Case Solution

AIC Systems, founded in 1992, was a printed circuit board producer for the personal computer industry. They specialized in motherboards and graphic cards. By the 2000s, the company had grown into an Original Design Manufacturer (ODM) encouraging innovation and new generation designs. In 2007, the company diversified into the production of Net-books. However, AIC is unable to meet the demand with the current operations. The production is neither efficient nor effective. The firm has a few options to improve the assembly line by either increasing the shifts or the assembly lines. Each of these options will increase the labor cost for the firm but facilitate in meeting the target production and cycle time.

Following questions are answered in this case study solution:

-

How efficient is netbook assembly at the Kaizhi plant?

-

What is the monthly output of the plant?

-

What is the theoretical efficiency of the planned line, looking only at direct labor on the assembly line?

-

What is the actual efficiency of the assembly line?

-

-

How effective is the current operation?

-

What are the right criteria by which to evaluate it?

-

Is the operation designed appropriately to meet demand?

-

-

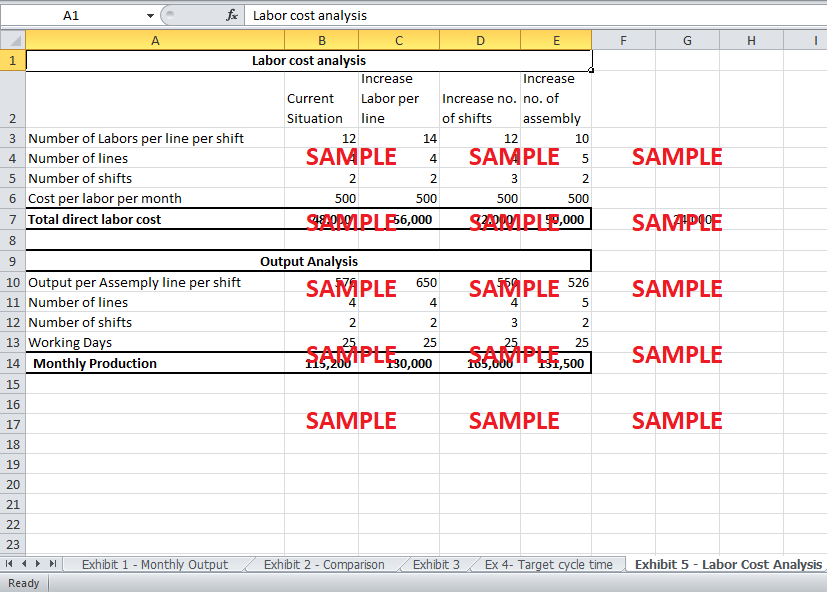

What is the financial impact of bringing the operation closer to full potential and achieving planned production levels?

-

What is the planned production level in terms of monthly output?

-

What is the financial impact of achieving the target cycle time?

-

How important is reducing direct labor as a means to improve financial performance? (Assume each assembly line worker costs $500 per month)

-

-

What recommendations would you make to Elias Chen?

AIC Netbooks Optimizing Product Assembly Case Analysis

1. How efficient is netbook assembly at the Kaizhi plant?

a. What is the monthly output of the plant?

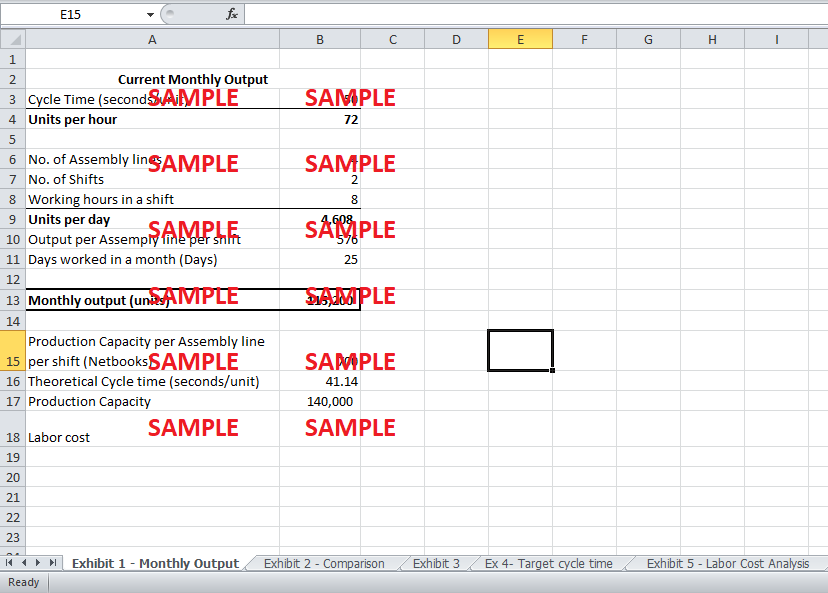

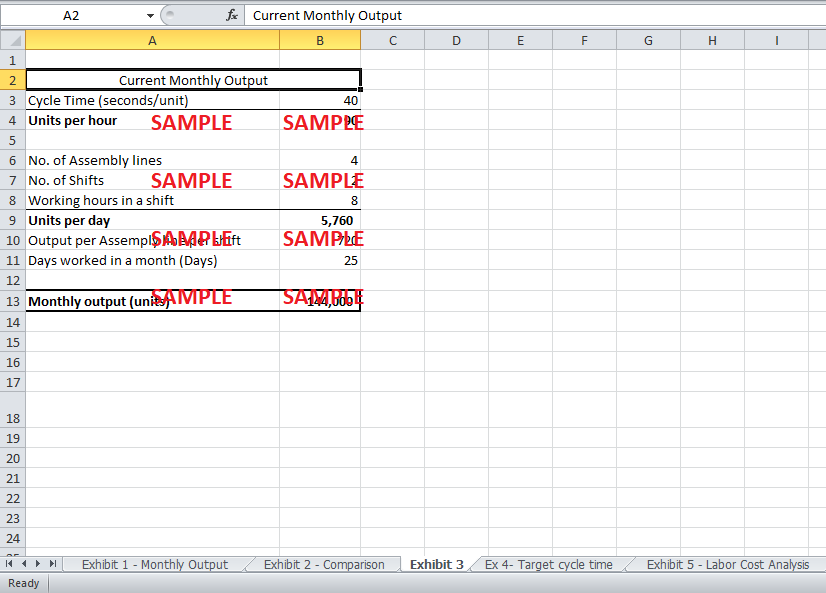

To determine the monthly output, the cycle time of 50 second per units is used. For the production of the notebook, there are four assembly lines and 2 shifts of 8 working hours. For calculations, it is assumed that there are 25 working days. Exhibit 1 shows the calculations for the monthly output of the plant in the current situation. The monthly production of netbooks would be around 115200 units.

b. What is the theoretical efficiency of the planned line, looking only at direct labor on the assembly line?

Looking only at the planned operations of the direct labor at the assembly line it is obvious that the actual operation is taking more time than the planned one. The planned time per station on one unit is nearly 40 seconds for all stations. On average, the theoretical time taken per station is around 39.6 seconds.

c. What is the actual efficiency of the assembly line?

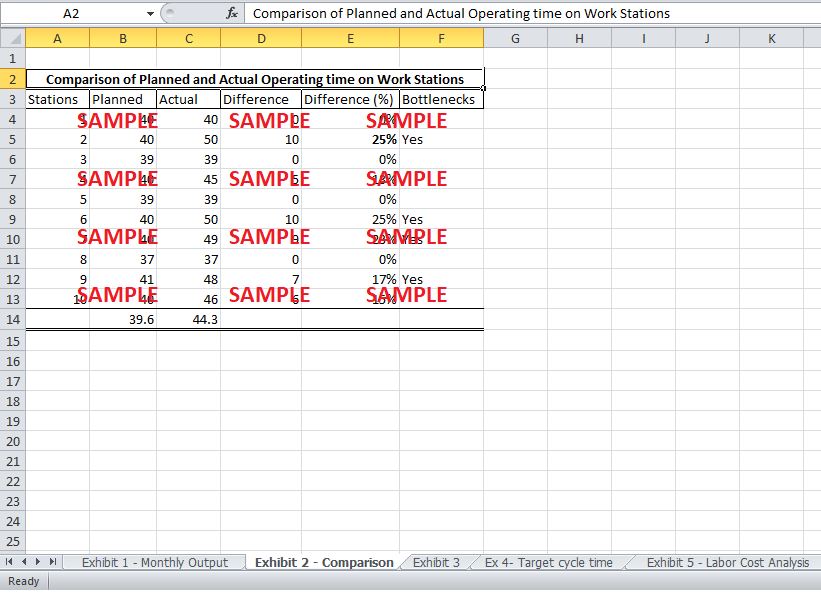

The average actual time taken by workers on each station to work on one unit in the assembly line is 44.3 seconds. Exhibit 2 shows the comparison between the planned and actual time of operations. The difference in the planned and actual time at each work station helps determine the bottlenecks. As stations 2, 6, 7 and 9 all take more than 15% time these are identified as the bottlenecks.

Furthermore, the planned worker per work station is one. However, there are more than one workers working in a station. It seems that because workers are helping each other, more than one worker is working in one work station. Rather than 10 workers in 10 stations as planned, there are 12 workers in 10 stations. This shows that the efficiency is very low. Despite, on average, more than one worker per station the time taken to finish the task on work stations is greater.

2. How effective is the current operation?

a. What are the right criteria by which to evaluate it?

The criteria by which to evaluate the current operation is first to examine the planned operations. It is important to note if the planned operations are not idealistic. If the planned operations are not realistic, it will set unreasonable goals for the workers which they would not be able to fulfill. Secondly, it is important to compare the actual operations with the planned one. It is obvious that the current operation is not effective because some non-standard operations have also taking place on the assembly line like the webcam requiring additional glue to be secured into the cover assembly frame.

b. Is the operation designed appropriately to meet demand?

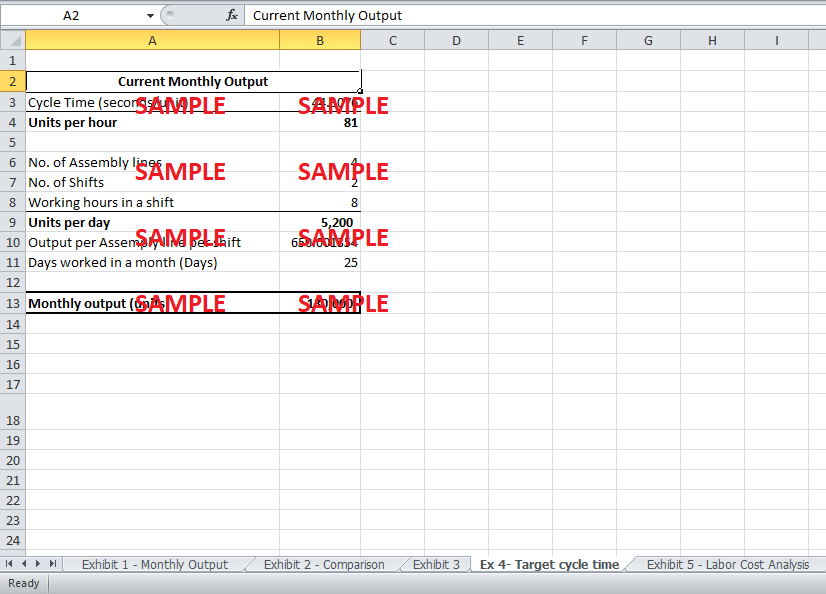

Yes, the operation is designed to meet the demand i.e. 130,000 Netbooks a month. Exhibit 3 shows that the operation is designed to produce as much as 144,000 units if each station takes nearly 40 seconds. However, there are bottlenecks at stations 2, 6, 7 and 9, which means that the operations might not be designed appropriately. The manager should re-evaluate the operation design and try to remove bottlenecks to improve the cycle time.

Hence, due to the existence of bottlenecks and problems with the operational designs, the current operation seems ineffective.

Get instant access to this case solution for only $19

Get Instant Access to This Case Solution for Only $19

Standard Price

$25

Save $6 on your purchase

-$6

Amount to Pay

$19

Different Requirements? Order a Custom Solution

Calculate the Price

Related Case Solutions

- Airbus A3XX Developing The Worlds Largest Commercial Jet A Case Solution

- ALDI A German Retailing Icon Case Solution

- Allied Electronics Corporation Ltd Linking Compensation To Sustainability Metrics Case Solution

- Allied Office Products Case Solution

- Alpen Bank Launching The Credit Card In Romania Case Solution

Get More Out of This

Our essay writing services are the best in the world. If you are in search of a professional essay writer, place your order on our website.