Get instant access to this case solution for only $19

Spreadsheet Analysis For Scharffenberger Chocolate Case Solution

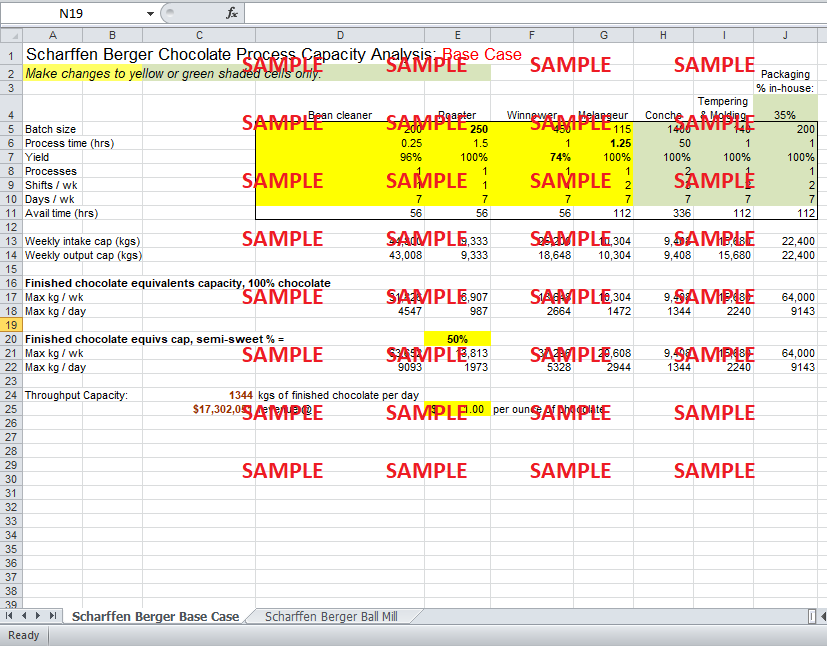

As per the information provided in the case and supported by the Excel sheet, the yield per hour of Winnower is only 74 percent which means a batch of 250 kg of whole beans can extract 185 kg of the nib. Therefore, the output is less than the input, and further calculation proves that it is exactly as per the yield i.e. 74 percent = [18,648 / 25,200].

Following questions are answered in this case study solution

-

Once you have replaced all the “???” cells with appropriate estimates, look at the column of numbers for the Winnower.

a. What precisely is the input to the winnower? The output? Why is the weekly intake capacity (in kilograms) so much higher than the weekly output capacity?

b. Looking at the Winnower step, the maximum kilograms per week for “finished chocolate equivalents” assuming 100% chocolate is half the amount of maximum kilograms per week for “finished chocolate equivalents” assuming 50% chocolate. Why is this true?

-

Notice that the “finished chocolate equivalents” do not vary for 100% chocolate or 50% chocolate for all conche and all processes downstream of it. Why is this the case? What happens at the conche stage that is fundamentally different from what happens before the conche?

-

Why is the concept of “capacity equivalents” needed to understand process capacity in this case?

-

Next, identify the process constraints for the current process (“Base Case,” Worksheet 1), and analyze how the product mix affects where the constrain is

What is the constraint(s) and total systems throughput at:

% chocolate

Constraint(s)

Throughput (daily kgs and yearly $)

99% unsweetened

82% extra dark

70% bittersweet

62% semi-sweet

41% milk choc.

-

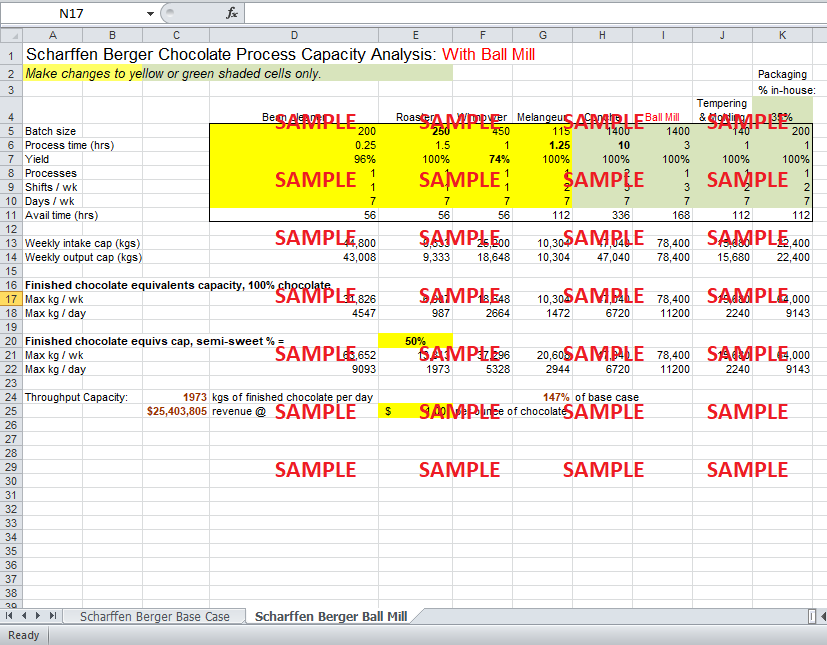

I then want you to repeat the analysis for the expanded operations (“With Ball Mill,” worksheet 2) What is the constraint(s) and total systems throughtput at:

% chocolate

Constraint(s)

Throughput (daily kgs and yearly $)

99% unsweetened

82% extra dark

70% bittersweet

62% semi-sweet

41% milk choc.

-

Change both spreadsheets to reflect a 62% semi-sweet product mix, and assume that the ball mill is now in place (worksheet 2)

a. What is the sequence of expansion steps required to double output from the base case capacity?

b. To triple output from the base case capacity?

c. Given your analysis, is there any capacity advantage to outsourcing the tempering and molding process? Explain why or why not.

Case Analysis for Spreadsheet Analysis For Scharffenberger Chocolate

b. Looking at the Winnower step, the maximum kilograms per week for “finished chocolate equivalents” assuming 100% chocolate is half the amount of maximum kilograms per week for “finished chocolate equivalents” assuming 50% chocolate. Why is this true?

This is primarily due to the fact that 100 percent chocolate means nearly all of it is cacao beans which usually take a much longer time to process. Cracking nibs out from a 100 percent chocolate is more time consuming than the case is with the 50 percent chocolate which is made up of half cacao beans, and the rest constitutes other ingredients such as sugar and flavoring (vanilla). Therefore, the quantity processed per week at the Winnower step for 50 percent chocolate is double the amount that is generated for 100 percent chocolate.

2. Notice that the “finished chocolate equivalents” do not vary for 100% chocolate or 50% chocolate for all conche and all processes downstream of it. Why is this the case? What happens at the conche stage that is fundamentally different from what happens before the conche?

This is primarily because in conche and beyond, the processes run for two cycles each lasting up to 8 hours. This allows for the greater quantity of different kinds of chocolates to be processed. Hence, this equality.

3. Why is the concept of “capacity equivalents” needed to understand process capacity in this case?

Process Capacity, in this case, is the production capacity of the different machines being used in the production process flow. Capacity equivalents are important to understand and analyze how much of the capacity is required to process the demand for different product types and how much time each process would require. This allows us to make a decision regarding the available bottlenecks in the process and how to counter these, alongside increasing capacity.

4. Next, identify the process constraints for the current process (“Base Case,” Worksheet 1), and analyze how the product mix effects where the constraint is. What is the constraint(s) and total systems throughput at?

|

% chocolate |

Constraint(s) |

Throughput (daily kg and yearly $) |

|

99% unsweetened |

Conching (Process time too high) |

997 kg per day; $ 12,830,205 |

|

82% extra dark |

Conching (Process time too high) |

1203 kg per day; $ 15,490,125 |

|

70% bittersweet |

Melangeur |

1344 kg per day; $ 17,302,051 |

|

62% semi-sweet |

Melangeur |

1344 kg per day; $ 17,302,051 |

|

41% milk choc. |

Melangeur (Shifts increased) |

1344 kg per day; $ 17,302,051 |

5. I then want you to repeat the analysis for the expanded operations (“With Ball Mill,” worksheet 2). What is the constraint(s) and total systems throughput at?

|

% chocolate |

Constraint(s) |

Throughput (daily kg and yearly $) |

|

99% unsweetened |

Conching (Process time too high) |

997 kg per day; $ 12,830,205 |

|

82% extra dark |

Conching (Process time too high) |

1203 kg per day; $ 15,490,125 |

|

70% bittersweet |

Melangeur |

1410 kg per day; $ 18,145,575 |

|

62% semi-sweet |

Melangeur |

1591 kg per day; $ 20,486,940 |

|

41% milk choc. |

Tempering |

2240 kg per day; $ 28,836,752 |

Get instant access to this case solution for only $19

Get Instant Access to This Case Solution for Only $19

Standard Price

$25

Save $6 on your purchase

-$6

Amount to Pay

$19

Different Requirements? Order a Custom Solution

Calculate the Price

Related Case Solutions

Get More Out of This

Our essay writing services are the best in the world. If you are in search of a professional essay writer, place your order on our website.