Get instant access to this case solution for only $19

Material Requirements Planning at A Cat Corp Case Solution

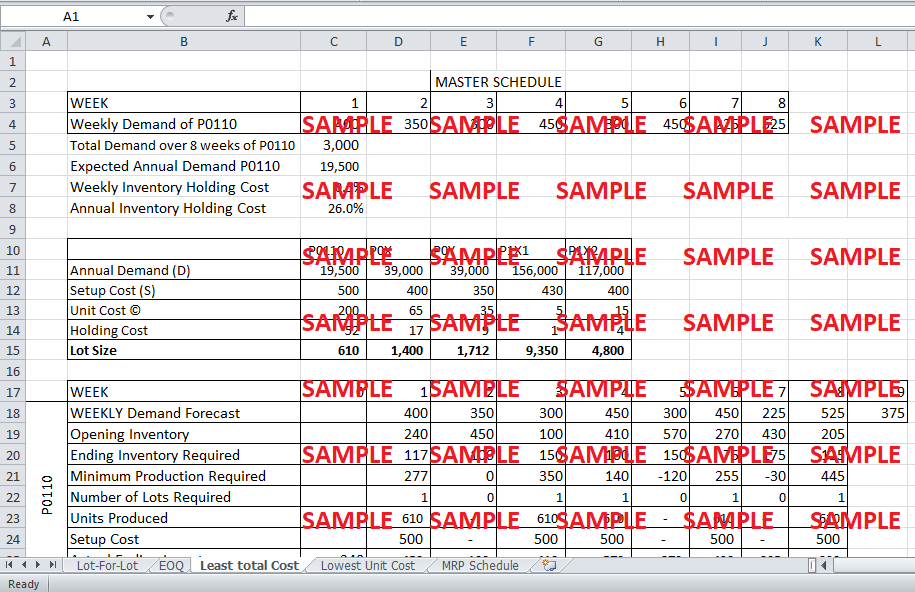

Lot sizing policy is a very important decision for inventory management. It could have a significant impact on the company’s performance. In a given situation, Sunita Menon, new personnel to inventory management has to propose a lot-sizing policy to her operations manager. Different possible policies could be a lot for lot technique, economic order quantity model, least total cost model, and lowest unit cost model. In order to analyze these policies, she had to segregate the costs which could be controlled using the lot-sizing policy. Since the cost of raw materials remains the same irrespective of lot sizes or quantity of production, they should be kept on the side from this analysis. Sunita had to calculate carrying costs and set up costs under different methods and then had to compare these numbers. Then she had to select a lot-sizing policy that would to formula the MRP matrix.

Following questions are answered in this case study solution

-

Help Sunita Menon decide the total cost of the P0110 units using the lot for lot technique.

-

What is the effect on the cost of the P0110 units if the economic order quantity technique is applied instead of a lot for a lot?

-

Should Menon elect to use the least total cost technique? Explain.

-

Evaluate the lot size by applying the least unit cost method.

-

Which method do you think Menon should apply in deciding the lot size for the P0110 units before she enters into the process of preparing the relevant MRP matrix? Explain.

-

Prepare the MRP matrixes for the P0110 units and the P0X units.

Case Analysis for Material Requirements Planning at A Cat Corp

1. Help Sunita Menon decide the total cost of the P0110 units using the lot for lot technique.

In the lot for lot technique, only such amount of output is produced in the period that is sufficient to meet the demand for that period so lot size may vary from period to period based on demand forecast. Detailed calculation is given in the attached excel file. Since in the case of A-CAT Corp. there are lead times involved at different steps, sufficient ending inventory should be available to meet demand in lead times. As the unit of lead times is not mentioned, it is assumed that lead times are presented in days. Assuming 6 days in a week, there should be an ending inventory of P0110 equal to around 34%(2/6) of demand for next week. Similarly, 50 % (3/6) of requirements of P0X and P0Y in next week should be present in ending inventory as it involves a further lead time of 1 day and 66% (4/6) of P0X1 and P0X2 should be present in ending inventory.

Opening balance of inventory for 1st week and demand forecast for 8 periods is given. Ending inventory required is calculated by the above assumption. Using this data, the amount to be produced is calculated by

Amount to be Produced = Ending Inventory + Demand Forecast - Opening Inventory

Average of demand forecast of 8 weeks is used to estimate the demand for the 9th week to estimate ending inventory in the 8th week. The same process is used to forecast the number of units produced by P0X, P0Y, P0X1, and P0X2.

Once the number of units to be produced of each item is decided, now estimate the cost of producing that level of output. Different costs related to the inventory policy are measured over the period of 8 weeks for analysis purposes between different inventory policies. Since the cost of raw material remains the same irrespective of lot-sizing decision, it is ignored for analysis purposes. Only relevant costs are carrying costs and setup costs.

The number of lots of each product is considered to be 1 in every period because it is assumed that a lot of every product is produced in every week. Setup cost for each lot is given. So total setup cost is calculated which comes out to be Rs 16,640 over a period of 8 weeks. In order to calculate the holding cost of inventory, the value of ending inventory in each period is calculated. Then the average value of total inventory in each period is calculated. Holding cost of inventory is given as 0.5% per week. So, holding cost is calculated for each period. The sum of holding cost over 8 week period comes out to be Rs 3,768.

The total variable cost which is the sum of holding cost and setup cost comes out to Rs 20,408 in using the lot-for-lot technique. One could observe that in using a lot for lot technique, holding cost comes out to be very low since only such amount of ending inventory is held to meet demand during lead times in next week. Also, the number of units produced in every lot may vary from one period to another. This increases the number of setups required leading to an increase in the setup cost.

2. What is the effect on the cost of the P0110 units if the economic order quantity technique is applied instead of a lot for the lot?

In economic order quantity (EOQ), different costs relevant to the product are analyzed as a setup cost, carrying cost to find an optimum order quantity which leads to minimized variable costs related to inventory. The formula used for calculating economic order quantity is as follows:

Where:

S = Setup Costs

D = Demand rate

P = Production cost

I = Inventory Carrying Cost

In this case, the annual demand for P0110 is calculated by an extrapolating forecast of 8 weeks to the whole year. Similarly, demand for P0X, P0Y, P1X1, and P1Y1 is calculated using the standard quantities. After that, the economic order or production quantity of each product is calculated using the above formula and taking values of unit cost, the setup cost and annual carrying cost. Inventory carrying cost is given as 0.5% for each. Annual carrying cost comes out to be 26%. After it, EOQ for each item is calculated. A comparison between the original lot sizes and EOQ for different products is given below:

|

|

P0110 |

P0X |

P0Y |

P1X1 |

P1X2 |

|

Original Lot Size |

613 |

1,226 |

1,839 |

2,452 |

1,839 |

|

EOQ |

612 |

1,359 |

1,732 |

10,159 |

4,899 |

It could be observed that original lot sizes and EOQ for P0110, P0X and P0Y are quite closer to each other, but EOQ for P1X1 and P1X2 is quite larger than original lot sizes. The major reason for this could be a significantly large setup cost relative to the unit product cost.

Once EOQ’s are decided, the minimum number of units required in each week of each product is calculated by considering the forecast as well as ending inventory requirements because of lead times. After it, a number of lot sizes for each product is calculated and this number would be zero when opening inventory is sufficient to meet the requirements of next week. Setup costs, inventory holding costs and cost of raw material are calculated for all products over a period of 8 weeks. It comes out that under EOQ method, ending inventory is quite higher than lot-to-lot sizing which leads to higher inventory holding costs. Total carrying cost is Rs 10,448 in using EOQ method while it is Rs 3768 in case of using the lot-for-lot technique. But setup costs in using EOQ method is Rs 8790 which is quite lower than Rs 16,640 when using a lot for lot technique. The cost of raw material is the same in using any technique. This one could conclude that the economic order quantity would lead to lower variable costs than a lot-for-lot technique by Rs 1,171.

Get instant access to this case solution for only $19

Get Instant Access to This Case Solution for Only $19

Standard Price

$25

Save $6 on your purchase

-$6

Amount to Pay

$19

Different Requirements? Order a Custom Solution

Calculate the Price

Related Case Solutions

Get More Out of This

Our essay writing services are the best in the world. If you are in search of a professional essay writer, place your order on our website.